Tel: 01925 44 44 64

HDR 777

Water recycling in high pressure cleaning

The use of the HDR 777 recycling plant in conjunction with professional high pressure cleaning systems offers decisive advantages. Compliance with legal regulations in terms of machines and environmental protection and the reduction of water and cleaning agent consumption by up to 80%.

Also concentration of hydrocarbons after treatment with HDR 777 is within limit values for waste water discharge.

Description

High-pressure cleaning is an outstanding technical solution to the problem of saving water.

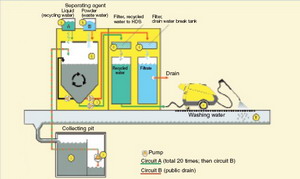

The installation and use of a water reclamation system for high pressure cleaner makes cleaning even more effective and environment friendlier. Wash water arising from the car wash, engine wash or parts cleaning first passes through a sludge trap to remove solid particles and is then treated in a compact high-pressure recycling plant in such a way that it can be reused for the washing process.

Installing the HDR 777 gives you a choice of two types of waste water treatment - depending on the application:

Wash water reclamation

In this case the waste water can be reused for further wash porcesses after it has been treated. The consumption of valuable fresh water is reduced by about 85 %, because it is used only for clear rinsing after the wash.

Waste water treatment

A chemical flocculation process binds and removes pollutants, such as oil, from the waste water so effectively that it can be discharged to public sewer without further treatment. The limit values for hydrocarbons are maintained.

Using the HDR 777 can avoid an expensive upgrade to an old or under-rated oil separator, because installation of HDR 777 requires no difficult building conversions.

Technical Description

Wash water from the high pressure wash is collected in a sludge trap and transferred from here to the HDR 777's reaction tank by a submersible pump. Depending onthe application, it is then mixed with a powder or liquid separating agent. Flocks form after thorough mixing and a brief period of contact. These flocks absorb the dirt particles and are then pumped to the filter unit together with the cleaned water. They are effectively separated from the water at this point. The sludge collected in this way must be disposed off properly in accordance with legal requirements.

The cleaned water is then available for further wash processes and is pumped as required to the high pressure cleaner.

Waste water treated with powder separating agent complies with the limits for hydrocarbons and may be discharged directly into the public sewer without need for any further treatment.

Application

Reclamation or waste water treatment for discharge of oily wash water arising from vehicle cleaning, engine washes and parts cleaning with high pressure cleaner.

The plant has a capacity of 200 litres/hour.

Suitable for: Petrol stations, workshops, car dealers, haulage companies and professional washers.

Features & Benefits

specially developed for treating wash water from high pressure cleaners,

maintains limit values for hydrocarbons,

effective waste water treatment,

saves up to 85 % fresh water,

unit in stainless steel,

simple construction,

operator and service friendly,

fully automatic operation.

Technical data HDR 777

-

Power supply (~/V/Hz) 1/240/50

-

Water flow rate (l/h) 600-800

-

Connected load (kW) 1.2

- Dimensions (L x W x H) 1300 x 630 x 1300

Technical data HDR 777 S.Steel

-

Power supply (~/V/Hz) 1/240/50

-

Water flow rate (l/h) 600-800

-

Connected load (kW) 1.2

- Dimensions (L x W x H) 1300 x 630 x 1300

Need More Information Please Contact Us ....