Tel: 01925 44 44 64

Low purchase and running cost with a real innovation in water recycling!

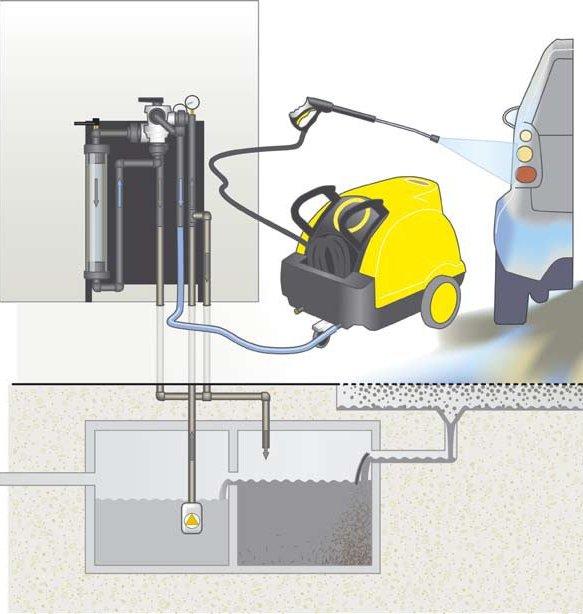

Recycling of washing water makes ecological sense and with new Karcher technology is now a very economical proposal for car dealers, workshops and smaller vehicle washes with a water consumption of max. 1000l/h. Karcher's new WRP 1000 unit which features the new, revolutionary Flat twisted system and have a water throughput of up to 1000 l/h, recycle oil-free washing water particulary effectively without needing any flocculents. Consumption of freshwater is reduced by up to 85%, since it is only used for clear rinsing.

Description

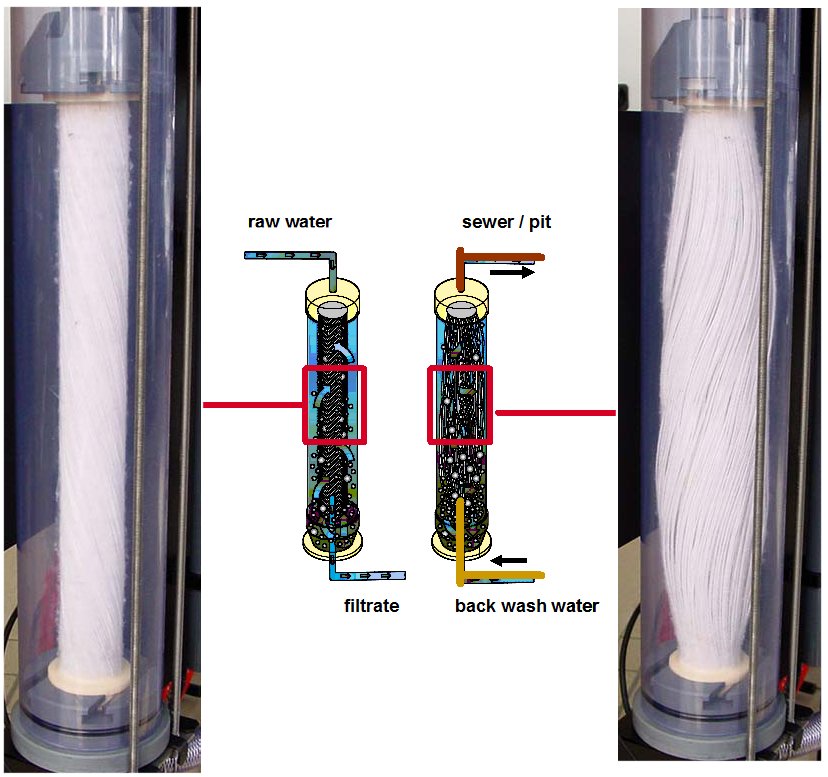

The reclamation of waste water is not only ecologically useful. Now with the new filtration technique of Kärcher it is also for car dealerships and car repair shops with a water demand less than 1000 l/h very economic. The WRP 1000 and its innovative Filatwist filter system with a water throughput of 1000 l/h ensures very effective reclamation of oil free waste water without dosing of flocculation chemicals. The consumption of fresh water is reduced up 85 %. Fresh water is only necessary for rinsing of vehicles during wash process. Due to low consumption of energy and simple installation the WRP 1000 classic stands out for very low investment and operation costs. Filatwist is the name of the new filtration technology developed by Kärcher. Hundreds of synthetic filaments are twisted together to form a filter through which the dirty water is routed. The filaments are loosened for backwashing so that they can be thoroughly cleaned with relatively little water. Filatwist reliably retains all particles larger than 5 µm, which helps to protect components that come into contact with water – such as gaskets, seals and valves. Neither an additional booster pump nor a storage tank or an electronic control are necessary for operation with a high-pressure cleaner. It is simply connected to the WRP 1000’s outlet valve. A continious circulation of water in the reclaim pit systems avoids smell problems as far as possible. The “classic” model is mounted on a wall and consists exclusively of mechanical components, i.e. no electricity is required. The treatment process and back wash of filter are controlled manually.

A continuous circulation of water in the reclaim pit systems avoids smell problems as far as possible.

Application

Water reclamation of oil free wash water from high pressure cleaners and vehicle wash plants with a water demand less than 1000 l/h

A revolutionary twist

The secret of Karchers innovative filtering system: modified polypropylene filaments which are twisted extremely tightly.

The advantages of this system:

- All dirt particles larger than 5μm are retained.

- The material can be cleaned and thus has a long service-life.

- the material needs to be replaced only about once a year.

The self-cleaning process is quite simple: the filaments are loosened and thoroughly backwashed from the inside out. that's all. A minimum of water is consumed in the process.

Water recycling with WRP 1000

The tanks

Waste water flows via a settling tank – where large particles settle – to the pump storage tank. From there it is pumped to the filter system. This is where the innovative Filatwist process comes into the picture.

The filterThe Filatwist system completely re tains all dirt particles larger than 5 μm. About 1000 litres of washing water are recycled per hour in continuous operation, saving up to 85% of drinking water.

Keeping odours to a minimum

In the WRP 1000 series constant circulation of the water in the tanks eliminates unpleasant smells almost completely. As long as no water is required by the plant or the high pressure cleaner, the washing water in the tanks is constantly circulated.

Self-cleaning process

A simple manual circuit starts the process (WRP 1000 eco and compact). With the WRP 1000 comfort, backwashing of the Filatwist media filter is auto - matic. In all cases, the backwashing process of the Filatwist system requires very little water.

Clear benefits of the Kärcher® innovation

- Exceptional performance at an attractive price

-

Revolutionary Filatwist filter system

-

Retention of particles > 5 μm

-

Fresh water saving of up to 85%

-

Throughput of 1000 litres/h

-

Longer service life of valves, pumps and gaskets of cleaning equipment

-

Direct water supply to high-pressure cleaner (no additional pump needed)

-

When used with high-pressure cleaner, no process water storage tank and no additional electronic control required

-

Low purchase and running costs

-

Minimum space requirement, simple installation

Technical data WRP 1000 Classic

-

Water flow rate (l/h) 1000

-

Weight (kg) 45

- Dimensions (L x W x H) (mm) 660 x 450 x 1100

Need More Information Please Contact Us ....

|

Karcher_WRP_1000_datasheet_1.217-108.0_PI_en_GB.pdf Size : 932.076 Kb Type : pdf |

|

Karcher_WRP-1000_operating_instructions_1.217-108.0_BTA_int_59566600_000.pdf Size : 431.448 Kb Type : pdf |

|

Karcher_WRP-1000_operating_instructions_2_1.217-108.0_BTA_int_59566600_000.pdf Size : 5431.506 Kb Type : pdf |